Right away, here’s the deal: oxidation on aluminum siding is not dirt, not mildew, and not the same thing as algae streaks. It’s a surface breakdown that turns paint or factory finish chalky, faded, and stubborn.

In Louisiana, where UV exposure stays strong, and humidity hangs around like an uninvited guest, oxidation on aluminum siding often shows up earlier, looks worse after a wash, and comes back faster if the underlying finish has already worn thin.

This guide explains what oxidation on aluminum siding looks like, why Louisiana homes get it so often, how to confirm it with a simple test, and how to clean it without wrecking the finish.

What are Oxidation on Aluminum Siding?

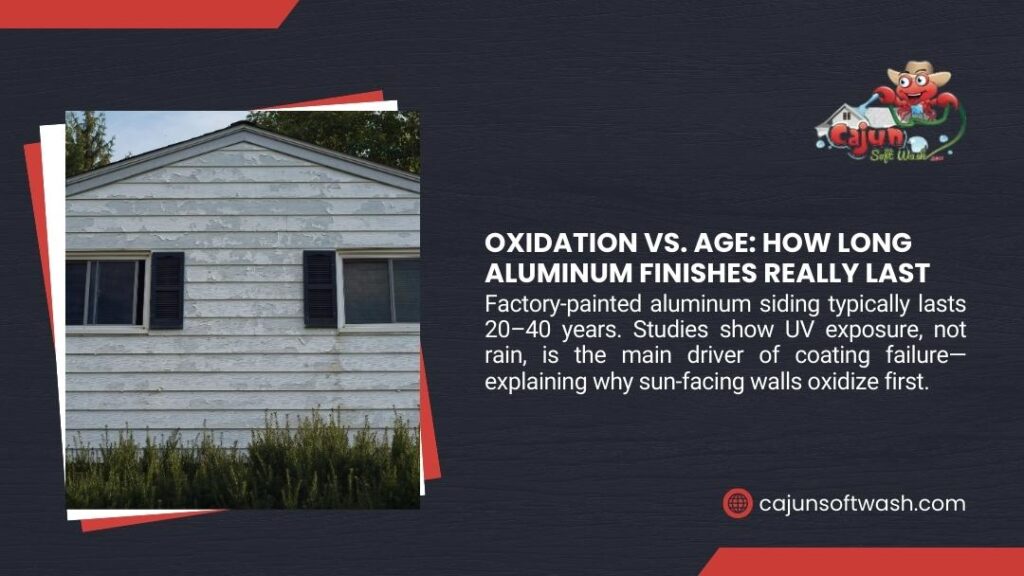

In plain terms, oxidation on aluminum siding is a chemical reaction at the surface. Aluminum naturally forms a thin oxide layer when exposed to air. That layer can protect bare metal, but most homes don’t have bare aluminum.

They have a painted or coated finish, and oxidation on aluminum siding usually means the coating has started to break down. When the binder in that coating degrades, pigment loosens, and you get the familiar chalky residue.

That chalkiness matters for two reasons. First, it makes the exterior look dull and uneven, especially in direct sunlight. Second, it blocks proper bonding if you try to touch up paint later. Military and government coating specifications treat chalk removal as real prep work, not a cosmetic extra, and they reference standardized chalk ratings for deciding whether the surface is ready to coat again.

What it looks like on painted aluminum vs bare metal

On most Louisiana homes, oxidation on aluminum siding shows as a powdery film you can wipe off with your fingers. The color depends on the paint: white residue on light colors, grayish residue on darker colors. On severely affected panels, the finish may look washed out, almost sun-bleached, with streaks that don’t rinse away.

Bare aluminum behaves differently. It can dull, haze, and spot, but it won’t usually produce the same pigment-heavy chalk. If the panels are painted, and most are, oxidation on aluminum siding is usually paint oxidation (coating breakdown), not bare-metal oxidation.

The hand-wipe test, and what it can’t tell you

Here’s what works: rub a dry, clean, dark cloth across the siding. If you get a powdery transfer, that’s a strong sign that oxidation on aluminum siding is present. Many cleaning pros use this wipe test to separate chalking from organic growth.

Here’s what it can’t tell you: how deep the oxidation goes. Light chalk may clean up and look far better. Heavy chalk can improve, but still look patchy because the finish itself has degraded unevenly. That’s why oxidation on aluminum siding sometimes looks worse right after a wash: cleaning removes surface grime, and the chalking becomes more visible.

Why does Louisiana siding oxidize faster than you expect?

Louisiana isn’t gentle on exterior finishes. You’ve got bright sun, long warm seasons, frequent rain, and moisture that stays in the air. Local climate summaries routinely show high annual precipitation totals, which means more wet/dry cycles and more surface film that bonds to siding.

On top of that, UV exposure remains a real factor across the Gulf region. UV index maps show high summer UV levels across the southern U.S., and Louisiana sits right in that high-UV belt.

That combination, UV + heat + moisture, pushes finishes toward breakdown. And once a coating starts to fail, oxidation on aluminum siding becomes much easier to trigger and harder to “clean away” permanently.

Heat, UV, humidity: why chalk happens

Coatings age. Under UV and heat, the resin that binds pigment loses strength. Add Louisiana humidity and regular rain, and the weakened surface sheds pigment as powder. The result is oxidation on aluminum siding, the chalk you see and the dullness you can’t ignore.

Louisiana’s humidity stats put many cities in persistently humid ranges year-round, which supports faster biological growth and keeps exterior surfaces damp longer. That doesn’t directly cause oxidation on aluminum siding, but it does keep the surface active and dirty, which increases washing frequency, another way weak finishes get stressed.

When oxidation shows up after pressure washing

People claim pressure washing caused oxidation on aluminum siding. Usually, pressure didn’t create oxidation from scratch. It removed grime and exposed what was already there. In some cases, high pressure can also accelerate failure by abrading a weakened coating. The result looks the same: chalk transfer, faded finish, uneven sheen, classic oxidation on aluminum siding, but now it’s impossible to unsee.

This is why careful technique matters, especially on older aluminum panels. If you want the short version for homeowners: pressure can rinse dirt, but it can’t rebuild a worn finish. If you’re unsure whether pressure is needed at all, understanding the differences in soft wash vs pressure wash can help you avoid putting a high-pressure wand on aging siding and risking unnecessary damage.

Oxidized Aluminum Siding Vs Oxidized Vinyl Siding

With oxidation on aluminum siding, you’re often dealing with paint oxidation or a degraded factory coating. With vinyl, it’s typically a weathered surface layer where UV changes the outer finish. That’s why you’ll see questions like “oxidation on vinyl siding after pressure washing” or “vinyl siding oxidation removal.” Those are real issues, but they don’t solve oxidation on aluminum siding by default.

What causes oxidation on vinyl siding

Vinyl oxidation is usually UV-driven surface degradation. It can look chalky, and people often search for how to remove oxidation from vinyl siding because ordinary house wash doesn’t fix it. The trick is that vinyl oxidation often needs specialty oxidation removers or restoration products, and results vary with age and color.

How to tell oxidation from mold, algae, and pollen haze

Louisiana makes this confusing because organic growth is everywhere. Here’s the practical distinction: mold, algae, and pollen sit on top of the surface and usually respond well to appropriate cleaners. Oxidation on aluminum siding is the surface itself failing, so the chalk returns as soon as you rub it, even after the siding looks clean.

If your siding has green film, black spotting near shade lines, or streaks under gutters, organic growth may be part of the story. On that side of the problem, discussions around Louisiana humidity and exterior cleaning help clarify how the climate drives organic growth and how that differs from oxidation issues on aluminum siding, making it easier to understand what’s really happening on the surface.

How to Clean Oxidized Aluminum Siding Without Wrecking the Finish

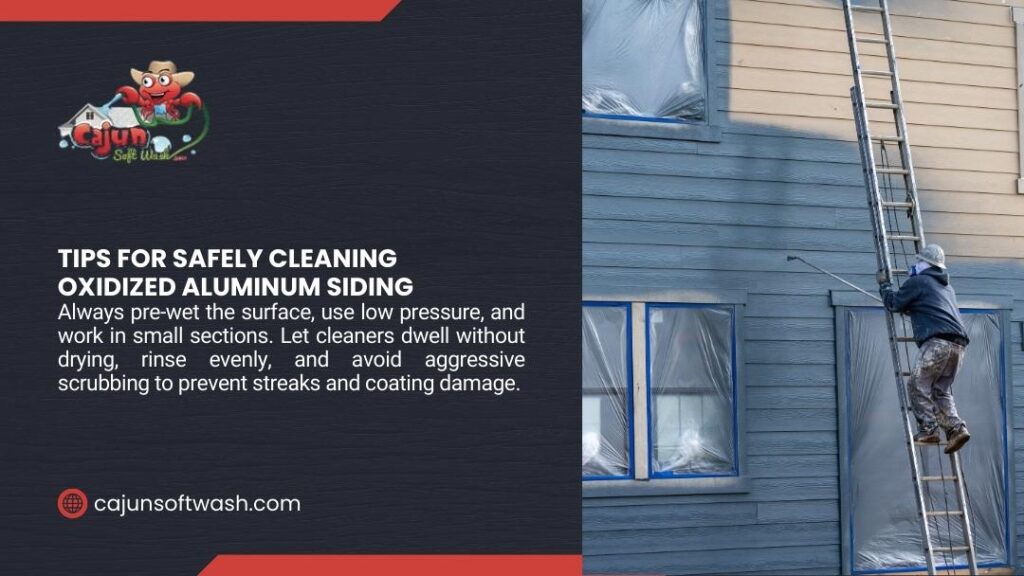

Cleaning oxidation on aluminum siding is all about control. Not brute force. You want a process that removes chalk and grime while limiting abrasion and minimizing streaking.

The best outcome comes from four things: wetting, correct dwell time, gentle agitation where needed, and controlled rinse pressure. When any of those go sideways, oxidation on aluminum siding tends to look blotchy.

A safe workflow that holds up in the real world

Start with a low-pressure pre-wet so the surface doesn’t drink chemistry unevenly. Apply a cleaning solution designed for exterior siding. Let it dwell, but don’t let it dry on the surface. Light agitation with a soft brush can help in heavy chalk zones, especially under eaves and where splashback hits. Then rinse with low to moderate pressure, keeping distance, angle, and flow consistent.

For homeowners looking to understand the process without contractor jargon, how to soft wash a house breaks down why oxidation on aluminum siding responds far better to the right method than to added force.

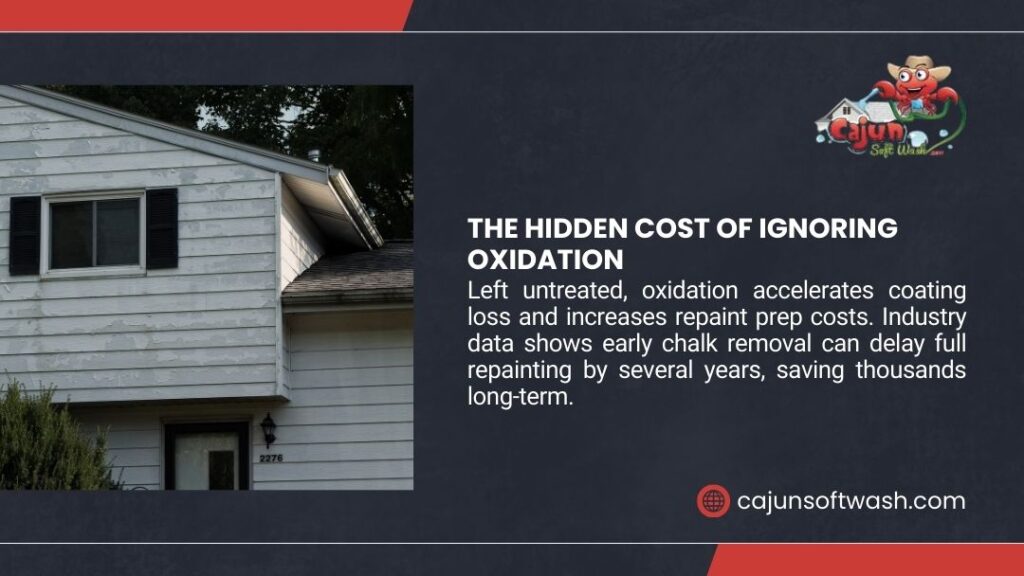

How to remove oxidation from painted aluminum

Oxidation on aluminum siding on painted panels isn’t always removable in the way people hope. You can remove chalk, you can improve appearance, but you can’t restore the original binder strength with cleaning alone.

That said, many homes still see a major visual upgrade when the chalk layer and embedded grime get stripped correctly. If the wipe test still produces heavy chalk after cleaning, that’s a sign the coating has degraded deeper. At that point, the fix for oxidation on aluminum siding shifts from cleaning toward surface restoration or repainting.

When mild cleaning works, and when you need an oxidation remover

Light oxidation on aluminum siding often improves with gentle cleaning, especially if the coating still has decent integrity. Moderate to heavy oxidation may need a dedicated oxidation remover product and careful technique to prevent streaks or uneven sheen.

What matters is not the label, it’s whether the product is meant to remove chalk and whether the surface is stable enough to tolerate agitation. Many house wash mixes target organic growth, but won’t fully address oxidation on aluminum siding.

Diagnostic table: what you’re really looking at

| What you see | What it usually means | Quick confirmation | Best first move |

| Powdery residue on the hand or the cloth | Oxidation on aluminum siding (chalking) | Dry wipe test shows chalk transfer | Controlled clean with light agitation in heavy zones |

| Green film, especially in shade | Organic growth | Growth fades with a proper cleaner | Soft wash approach, then reassess for oxidation on aluminum siding |

| Black streaks beneath gutters | Often, organic staining or runoff film | Cleaner lifts it without chalk transfer | Treat runoff stains first; then test for oxidation on aluminum siding |

| “Clean” siding still looks faded | Coating degradation | Chalk returns quickly after cleaning | Consider a restoration product or a repaint plan |

How to Remove Oxidation From Aluminum Siding: DIY Vs Professional Results

DIY can work for mild cases. But DIY also goes sideways fast on older aluminum. The reason is simple: oxidation on aluminum siding behaves differently panel to panel, especially on elevations that face full sun. That unevenness is where streaking and patchy sheen come from.

Professionals tend to get better results because they control dwell time, rinse flow, and agitation with less abrasion. They also know when to stop trying to wash away a failing coating and move toward the real solution.

Getting a sense of what residential cleaning services typically include, beyond just siding, helps put issues like oxidation on aluminum into perspective as part of a broader exterior maintenance plan for the home.

What DIY can realistically achieve on heavy chalking

Heavy oxidation on aluminum siding can improve, but it often won’t become like new. You may reduce the chalking and brighten the color, yet still see unevenness because the finish has degraded. That’s not a cleaning failure; it’s a material condition.

This is also where homeowners overuse pressure. If you chase oxidation on aluminum siding with higher PSI, you risk etching, denting older panels, or stripping more of the weakened coating. The siding might look temporarily brighter, but it can also look more uneven within weeks.

When repainting becomes the smarter fix

When chalk returns immediately after cleaning, and color looks flat even when the surface is clean, repainting may be the durable fix for oxidation on aluminum siding. Prep is the make-or-break step here. Coating guidance in formal specifications treats chalk removal as essential prep, with standardized testing for chalk level before recoating.

If you decide repainting is on the table, the logic is straightforward: cleaning removes loose chalk and contaminants, then primer and topcoat rebuild protection. That’s why many paint pros describe chalky siding as a bonding problem, not just a cleaning problem.

Method comparison: Choosing the Right Fix

| Approach | Best for | What you gain | Main risk | Typical durability |

| Controlled cleaning | Light + surface film | Brighter appearance, less chalk transfer | Patchiness if rinse and agitation vary | Months to a couple of years, depending on coating health |

| Oxidation remover + gentle agitation | Moderate | More chalk removal, better uniformity | Streaks ifthe product dries, or if agitation is uneven | Often longer than basic wash, still limited by coating condition |

| Prep + repaint | Heavy | Restored color, stronger protection | Poor prep leads to early peeling | Multi-year performance with proper prep and coating system |

How to Paint Oxidized Aluminum and Make It Last in Louisiana

Painting over aluminum siding without proper prep is a fast track to disappointment. In Louisiana’s heat and moisture, weak prep shows up quickly as peeling, bubbling, or uneven gloss.

A durable repaint hinges on three conditions: the chalk must come off, the surface must be clean and dry, and the coating system must suit exterior metal and local exposure. The chalking stops paint from bonding. The point is widely emphasized by painting pros because it’s the failure mode they see most.

Metal Roof Oxidation Removal: Where it Overlaps, Where it doesn’t

Many homeowners ask for metal roof oxidation removal because the idea sounds similar. The overlap is the weathered coating, not the material. A metal roof may have coating oxidation, but it also has seam design, fasteners, and coatings that differ from siding.

The safest takeaway is this: if you see chalking on a coated metal surface, cleaning may help, but the long-term solution often comes from coating restoration or recoating, similar in logic to oxidation on aluminum siding, but not identical in chemistry or technique. If you’re already maintaining other exterior surfaces, pairing siding work with a broader exterior plan can save time. A primer on exterior home cleaning can help you stage projects without turning your weekends into a never-ending scrub-a-thon.

Conclusion

If you’ve confirmed oxidation on aluminum siding with the wipe test, your next move should match the severity. Light chalk often responds well to a controlled wash. Moderate chalk may need an oxidation remover and careful technique. Heavy, persistent chalk points to prep-and-repaint territory, because the finish itself has worn out.

If you want a professional assessment without guesswork, a reputable soft wash company can evaluate the siding condition, explain what improvement is realistic, and keep you from fixing oxidation on aluminum siding by accidentally stripping the finish.

For homeowners, you can start by reviewing Cajun Softwash’s approach to soft washing and decide whether your siding needs a gentle wash, oxidation treatment, or a longer-term restoration plan.